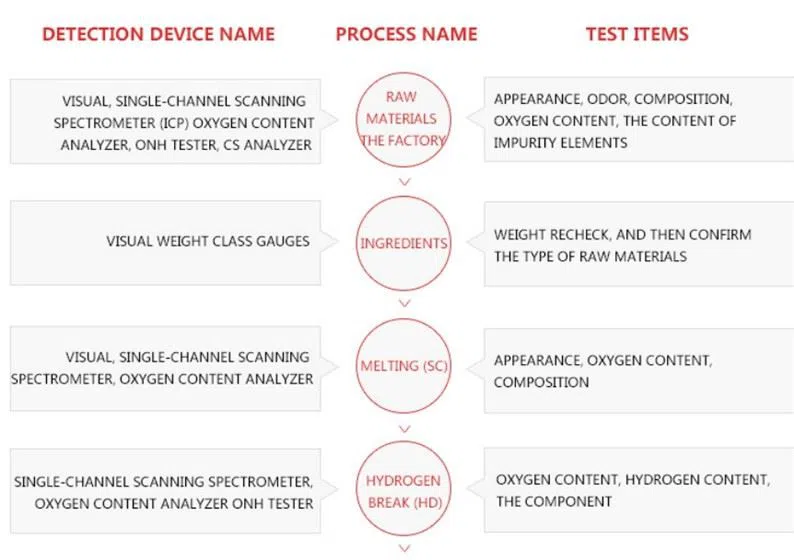

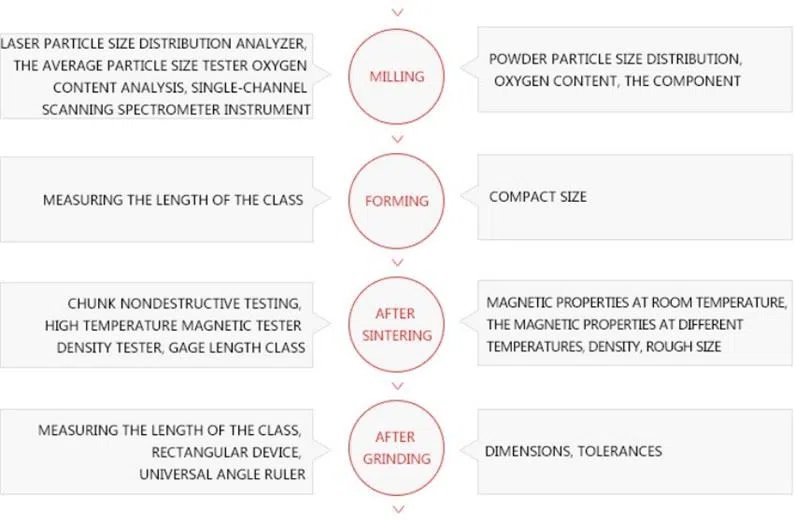

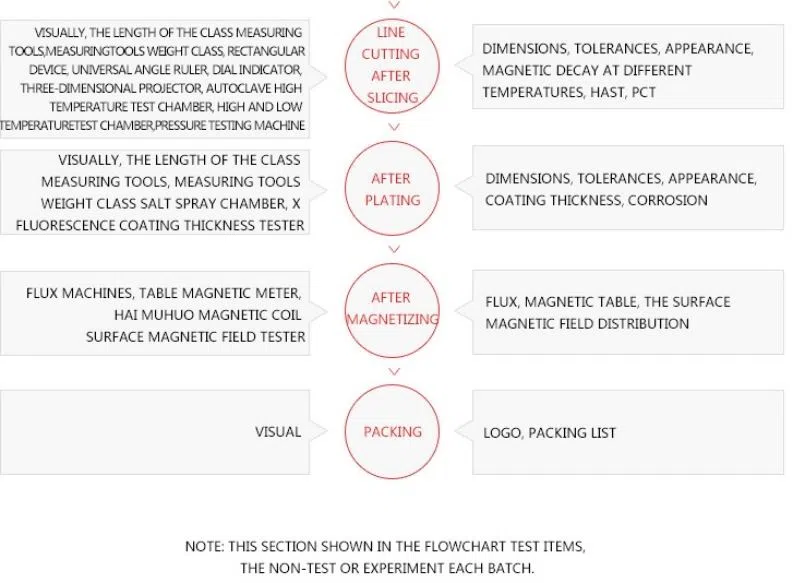

Process Control

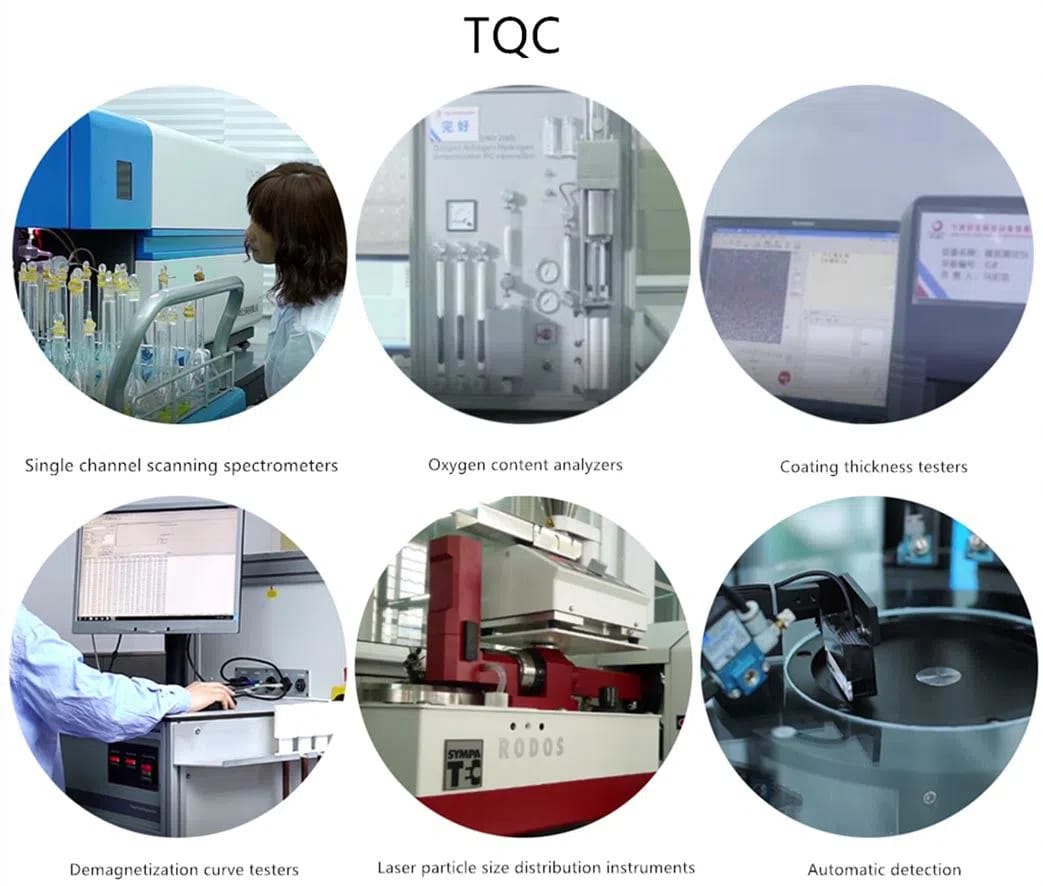

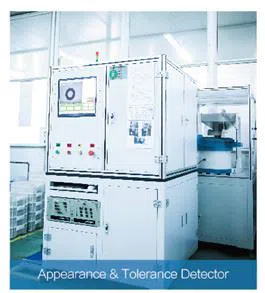

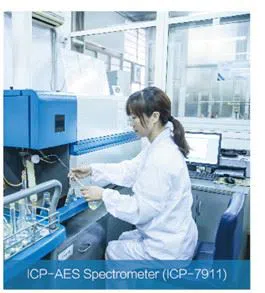

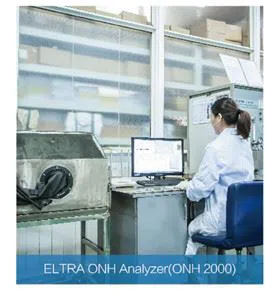

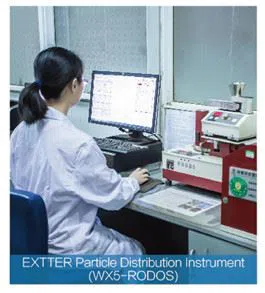

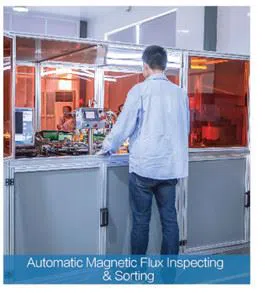

In terms of quality control, the company has monitoring means for the whole process from raw materials to factory inspection, and adopts various advanced testing instruments to ensure the quality stability of each key product. Before the raw materials are put into the warehouse, the oxygen content tester, single channel scanning spectrometer, carbon sulfur analyzer, oxygen nitrogen hydrogen analyzer and other analytical instruments are used to control the quality of raw materials; For process products, laser particle size distribution instrument and Hurst performance test equipment are used to ensure that the process products are qualified and the blank performance meets the specification requirements; For black film products and finished products, three-dimensional projector, high temperature test chamber, high and low temperature alternating damp heat test chamber, hat test chamber, salt spray test chamber, X-ray fluorescence coating thickness tester, appearance automatic imager, etc. are used to ensure product quality. In the process of magnetic flux inspection, advanced automatic magnetic flux grading test equipment is adopted to ensure the stability of product inspection and provide excellent quality assurance for ex factory products.

Testing Equipment

Our Sales Team